Mill Finish Aluminium Circle vs. Anodized Aluminium Circle for Industrial Applications

Aluminum circles are an ideal material choice for industrial applications because of their light weight corrosion resistance, lightweight, and thermal conductivity capabilities. In deciding between mill finish aluminium circles and anodized aluminium circles for particular applications however, both the mill-finish and anodized models can have a significant impact on the performance and longevity of the product. This guide will explain the distinctions between the two to help you decide which one is best suited for your.

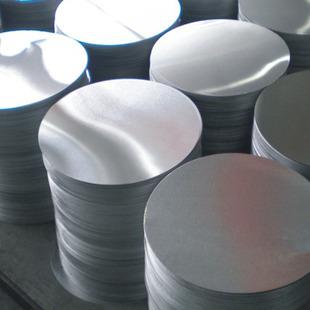

What is Mill Finish Aluminium Circle

The mill finish Aluminum circles are raw and uncoated aluminum discs that retain their natural surface right from the milling machine. In contrast to polished or anodised aluminum and do not undergo any other finishing processes which gives them a rough and matte appearance, with metallic shine.

These circles are appreciated due to their low price and flexibility, which makes ideal for use in areas in which practicality is a priority over the aesthetics of the surface. Since they’re not treated to any kind of treatment, they are able to be cut or stamped, spun or machined into a range of shapes, such as reflectors, cookware, or industrial elements.

Mill finish aluminium is more susceptible to scratches and oxidation than treated aluminum. Certain manufacturers apply protection coatings, or even additional methods of processing like painting or polishing to ensure longevity over time.

The Key Advantages:

- Lower production cost (no extra finishing steps)

- Fantastic formability and fabrication

- Ideal for processing in secondary ways (painting coating, painting, etc.)

A popular choice for kitware, lighting components, and general industrial parts where a fine appearance isn’t essential.g components, and general industrial parts where a refined surface finish is not critical.

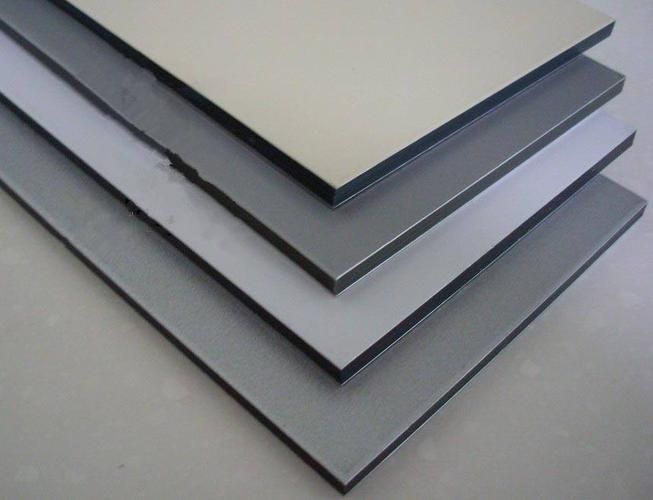

What is Anodized Aluminium Circle

Anodized aluminum circles go through an electrochemical process that strengthens the oxide layer that gives them a longer-lasting and corrosion-resistant surface. The process involves soaking the aluminum in an electrolyte solution that is acidic before the application of an electric current that creates layers of oxide, and then close pores. Through this process, the material becomes stronger and more durable, and is dyed with different colours to enhance the look.

A single of the major advantages of anodized aluminum is its remarkable resistance to the elements, which makes it the perfect material for outdoor and high-wear projects. As opposed to the mill finish aluminum circles that are anodized, they do not require additional coatings to protect them as the process itself gives long-lasting protection from UV rays and exposure to chemicals.

Additionally, anodized aluminum offers better adhesion to adhesives and paints and makes it a great option for industries that require adhesives or printed parts. Most commonly it is utilized in automotive trim and architectural panels, electronic housings, and top-quality consumer products for which aesthetics and quality are crucial.

Comparison: Mill Finish vs. Anodized Aluminium Circles

If you are considering aluminum circles for industrial applications it is essential to be aware of the major distinctions between anodized and mill-finish variations. Mill finish aluminum offers an affordable raw material with excellent formability, making it suitable for applications that require secondary processing. The oxide layer that it has naturally protects against corrosion in a basic way but exposure for long periods to harsh environments can require further protective coatings. The non-polished surface is great for products where appearance is in the way of the functionality, such as spinned cookware or reflector panels.

However, anodized aluminum circles work well in tough environments. Electrochemical anodizing creates an extremely dense oxide layer that improves the resistance to corrosion surface hardness, as well as endurance. The treatment also allows the dyeing of colors and is therefore ideal for use in consumer and architectural. Although anodized aluminum is more costly over mill finishes, it’s durability and low maintenance requirements could surpass the higher initial cost in critical applications.

The decision between the two is based on the project’s requirements in terms of durability, appearance and cost. Below is a more detailed comparison:

| Property | Mill Finish Aluminium Circle | Anodized Aluminium Circle |

| Surface Characteristics | Natural matte finish, slightly rough | Smooth, uniform, color options available |

| Corrosion Resistance | Moderate (requires protection in harsh environments) | Excellent (built-in oxide barrier) |

| Hardness & Durability | Standard aluminium hardness | Increased surface hardness (resists scratches) |

| Cost Considerations | Lower initial cost | Higher due to processing, but lower lifetime costs |

| Aesthetic Flexibility | Limited (requires post-processing for colors) | Wide color range, premium finishes |

| Maintenance Requirements | Regular cleaning/protection needed | Low maintenance, easy to clean |

| Common Applications | Cookware, reflectors, industrial blanks | Architectural cladding, automotive, electronics |

This analysis reveals how each one is suited to specific industrial requirements and requirements, with mill finish being the most economical option for fabrication, and anodized being the most effective choice for high-end, decorative applications.

Choosing the Right One for Different Industrial Applications

The choice between mill finish and anodized aluminium circles will depend on the particular requirements of your industrial project. Here are the most important industrial uses along with specific guidelines for each kind:

Cookware & Kitchenware Manufacturing

Mill Finish Aluminum Circles are the preferred material choice for pots, pans and pressure cooker bases due to their soft yet malleable nature allowing deep drawing without cracking, as well as being an excellent base material when polished or non-stick coated for use in cookware.

Anodized Aluminium Circles are used in premium cookware where scratch resistance and easy cleanup are key features. Hard-anodized cookware offers superior durability; however, its higher cost makes mass-produced items less common.

Lighting & Reflectors

Mill Finish is a great choice to use for lamps and reflectors due to its bright natural surface provides excellent light reflection without the need for additional treatment. The low cost makes it suitable for production on a large scale.

Anodized Aluminium is utilized in the most expensive lighting fixtures where the resistance to corrosion (e.g. outside lighting) or colored finishes (decorative lighting) are essential. The anodized layer stops the oxidation process, preserving the reflectivity throughout time.

Automotive Components

Mill Finish is typically utilized in structural parts for interior use including heat shields and brackets where surface finish isn’t a major factor. Because of its light weight composition and shapeability mill finish makes an ideal choice for machined or stamped components.

Anodized aluminum is the most popular material for wheels, exterior trim and other decorative elements because of its weather-proofing and attractive appearance. Additionally its hard anodized coating shields against the accumulation of road debris and exposure to chemicals.

Architectural Cladding & Decorative Panels

Mill Finish is not often employed in architectural design without being painted or powder-coated because it is not weather resistance. It could be used as a base material to further finishing.

Anodized Aluminium is the most popular choice for signs, facades and interior design due to its colour stability as well as UV resistance and low maintenance. The anodized coating provides decades of service without fading or peeling.

Electronics & Heat Sinks

Mill Finish is a great option on standard heat sinks as well as electronic enclosures in which thermal conductivity is the main goal as well as surface preparation is not necessary.

Anodized aluminium is generally regarded as the best choice used in thermal heat exchangers with high performance due due to the anodized layer, which improves heat dissipation and also protects it from thermal and corrosion radiation. Black anodized surfaces also improve the thermal radiation.

To Conclude

The choices between mill finish and anodized aluminum circles depend on the requirements of your undertaking. Mill finish provides the ease of working and lower in cost, which makes it ideal for projects where additional processing is needed. For strength, durability, corrosion resistance and visual attractiveness anodized aluminum is regarded as a top choice. It’s designed for applications that require top performance and decorative finishes as well. By considering the environment, budgetary constraints and the requirements for surfaces Manufacturers can select the best material for maximum efficiency and performance over the long term.

Related Products