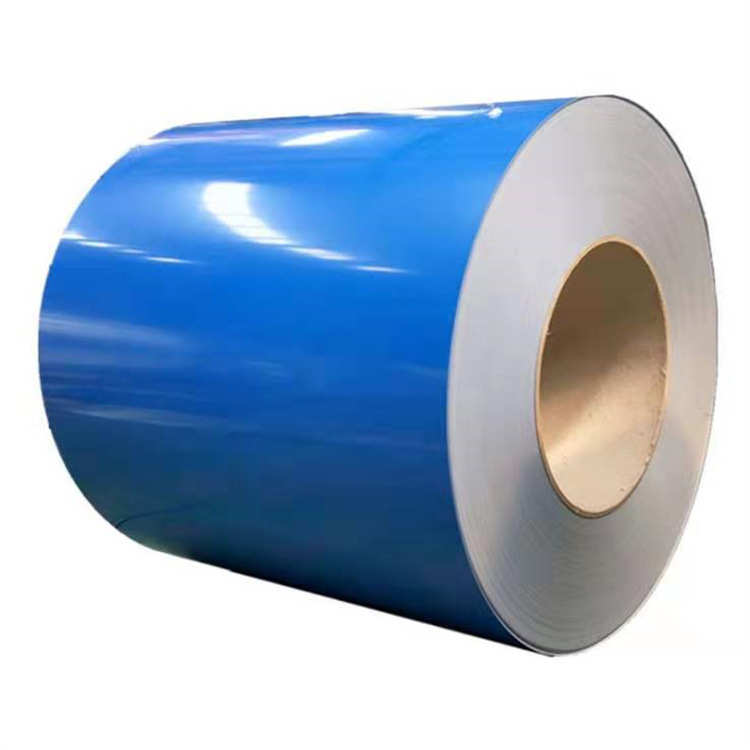

PVDF vs. PE Coated Aluminum Coil: Which Costs More?

The price of a coated aluminum coil is a critical factor for businesses in industries such as construction, transportation, and signage. When comparing PVDF (polyvinylidene fluoride) and PE (polyester) coatings, the cost often comes down to a balance of performance and application-specific needs. So, which coating costs more? In general, PVDF-coated aluminum coils are more expensive due to their superior durability and long-term performance, while PE-coated coils are more affordable and suitable for budget-conscious projects.

This article will explore the factors affecting coated aluminum coil prices and provide a detailed comparison of PVDF and PE coatings, helping you make an informed decision.

Core Factors Influencing the Price of Coated Aluminum Coils

The price of coated aluminum coils is determined by multiple interrelated factors, ranging from raw material composition to market dynamics. Below is a detailed breakdown of the key elements affecting pricing:

- Base Material Composition

Alloy Type:

- 1000-series pure aluminum (e.g., 1050, 1060) is cost-effective but less durable, suitable for general-purpose applications.

- 3000-series alloys (e.g., 3003, 3004) contain manganese, offering enhanced strength and corrosion resistance, with prices 10–15% higher than pure aluminum.

- 5000-series alloys (e.g., 5052, 5083) incorporate magnesium, providing superior durability for harsh environments, priced 20–30% higher than 3000-series.

Aluminum Purity:

Higher-purity aluminum (≥99.7%) reduces impurities, improving formability but increasing costs by 5–8% compared to recycled or lower-grade variants.

- Coating Technology and Performance

Coating Type:

| Coating Type | Price Range (USD) | Key Features |

| Polyester (PE) | $2–$7/m² | Cost-effective, moderate durability |

| Fluorocarbon (PVDF) | $7–$21/m² | UV-resistant, 15–20 years lifespan |

| Antimicrobial/Self-clean | +$0.5–$2/m² | Specialized applications (e.g., labs) |

Coating Layers:

- Single-layer coatings are economical but less durable.

- Double-layer (primer + topcoat) or triple-layer systems increase costs by 15–30% but extend service life to 15–20 years.

Customization: Special colors, finishes, and dimensions may increase costs.

- Thickness and Dimensions

Thickness:

Thicker coils (e.g., 1.0 mm vs. 0.3 mm) require more raw material and energy, raising costs by 5–8% per 0.1 mm increase.

For example, a 0.5 mm coil may cost $5/m², while a 1.2 mm version exceeds $12/m².

Width and Length:

Non-standard sizes (e.g., ultra-wide coils for industrial roofing) incur 5–20% additional processing fees.

- Order Volume and Supplier Selection

Orders above 10 tons often receive 5–15% discounts due to economies of scale. For example, a 20-ton order of 3003 alloy coils might cost $3350/ton, versus $3500/ton for small batches.

Established coated aluminum coil manufacturers (e.g., China Zhongwang, Alcoa) charge 8–12% more than smaller vendors but guarantee consistent quality and certifications (e.g., ISO 9001, ASTM B209). Lanren is a smaller aluminum factory in China than them, but we are also professional to produce high-quality aluminum products like circles, coils, sheets etc. Feel free to contact us for your needs.

Understanding these factors enables you to optimize budgets while ensuring performance requirements are met.

Cost Comparison: PVDF vs. PE Coated Aluminum Coils

PVDF and PE-coated aluminum coils have different cost aspects, including raw material cost, manufacturing complexity, durability, maintenance requirements and market trend. Below are the breakdown:

- Raw Material Cost: PVDF uses high-grade fluoropolymer resins which are more expensive but more durable and weather resistant. PE uses polyester resins which are more affordable but less robust.

- Production Cost: PVDF-coated aluminum coils are more complex and energy consuming, multiple layers and advanced curing techniques are involved. PE-coated coils are simpler and faster to produce, more cost effective for lower end applications.

- Durability and Lifespan: PVDF coatings can last 20-30 years, way longer than 5-10 years of PE coatings. So while PVDF is more expensive upfront, it can save you money in the long run by reducing replacement frequency.

- Maintenance and Repair: PVDF-coated coils require minimal maintenance due to its superior weathering and UV resistance. PE-coated coils may need more frequent repairs or replacement, which can increase lifecycle cost.

- Market Trend: PVDF-coated aluminum coils are priced between $7.00 to $21.00 per square meter, premium quality. PE-coated coils are priced between $2.00 to $7.00 per square meter, more affordable for budget conscious projects.

| Factor | PVDF Coating | PE Coating |

| Raw Material Cost | High | Low |

| Production Complexity | High | Moderate |

| Lifespan | 20-30 years | 5-10 years |

| Maintenance | Low | High |

| Typical Price Range | $7–$21/m² | $2–$7/m² |

Choosing the Right Coating for Your Needs

When to Choose PVDF-Coated Coils

- Long-term projects requiring superior durability and weather resistance.

- Applications exposed to harsh environmental conditions, such as marine or industrial zones.

- High-end projects where aesthetics and performance are priorities.

When to Opt for PE-Coated Coils

- Budget-conscious projects with short-term requirements.

- Indoor applications or areas with mild environmental exposure.

- Projects needing vibrant and customizable finishes at a lower cost.

By understanding these differences, you can select the coating that aligns with your project’s performance requirements and budget constraints. If you are looking for a China Coated Aluminum Coil Supplier, Lanren is your reliable choice. For tailored recommendations or quotes, contact our team today!

Related Products