What’s the Aluminium Circle Sheet Used For?

Aluminium circle sheets have become popular across various industries due to their lightweight, corrosion resistance and excellent formability. Cut from aluminium coils or sheets, these discs can be found in cookware, lighting, electronics and decorative applications such as cookware. In this article we will look into their manufacturing process, key applications and common alloys.

What are the Aluminium Circle Sheet Manufacturing Process?

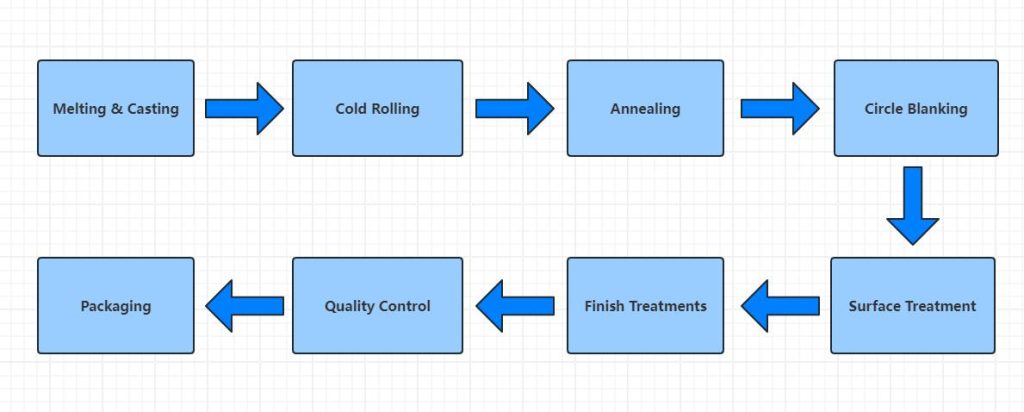

Aluminium circle sheet production is a sophisticated multi-step process that focuses on the optimum quality and performance:

- Melting & Casting: The Aluminium ingots are melted and cast via direct chill casting (DC), which produces large slabs with homogeneous structures. After being preheated for hot rolling (heating + rolling), the thinner strips (typically 2-10mm thick) can then be produced for improved workability.

- Cold Rolling: Cold rolling is performed at room temperature to reduce thickness further, improve surface finish and mechanical properties, quality of surface finish, and mechanical strength.

- Annealing: Annealing softens metal so that efficient deep-drawing applications such as cookware can be carried out.

- Circle Blanking: Hydraulic or mechanical punches with exact tolerances create round discs of exact diameter tolerance (+/-0.1mm).

- Surface Treatment: After they have been punched out of sheets, precision punches use hydraulic or mechanical force to punch discs of round shapes into discs of precise sizes (+/-0.1mm).

- Finish Treatments: Can have anodizing (for illumination use), coating (use in cookware), or polishing (use in decorations).

- Quality Control: Aluminium discs undergo rigorous thickness consistency, flatness, and surface imperfections testing prior to being packed to ensure that they meet industry standards for strength, corrosion resistance, and formability. This rigorous testing regime ensures aluminium discs function in any application in industries.

What are the Main Applications of Aluminium Circle Sheet?

Aluminium circle sheet is among the more adaptable metals, renowned for its lightweight and excellent thermal conductivity. They also have great durability against corrosion, as well as easy manufacturing. This makes them perfect for a range of consumer and industrial applications. Below, we will explore the main uses of aluminium circles in greater detail.

Non-stick Coated Aluminium Circle for Cookware

The most popular uses for aluminum circles is to create cookware. Due to their excellent conductivity to heat, non-stick coated aluminum circles are employed to make pans, pots and baking trays as well as pressure cookers made from aluminum circles.

- Non-Stick Coatings: Modern cookware items typically contain Teflon along with ceramic coatings that are put directly on aluminum circles to prevent food from sticking and aid in cleaning. The coating stops food from sticking, and helps in cleaning up.

- Even Heat Distribution: Aluminium ensures uniform heat distribution, and removes hot spots that can ignite food items and increase cooking time.

- Durable yet Lightweight: Aluminium cookware offers the lightest weight and long-lasting durability in comparison to stainless steel or cast iron equivalents.

- Cost-Effective Production: The malleability of aluminium allows for cost-efficient printing and deep-drawing techniques that produce efficient cookware designs with the least waste.

Anodized Aluminium Circle for Lighting

Anodized aluminium circles are a vital part in lighting fixtures, especially reflectors, LED lamps, or lamp housings.

- Reflectivity: Aluminum alloys that are high-purity, like 1050 and 1060, have superior light reflection and make it the ideal reflective material for LEDs as well as streetlamps.

- Heat Dissipation: LED lights generate heat. However, aluminium can dissipate heat thermally to prolong the life of lighting devices.

- Anodized Finishes: Anodizing aluminium circles increases their aesthetic appeal, but also impacts their functionality due to the corrosion-resistant layers which improve their anodized anodic coatings.

- Lightweight and Rustproof: Aluminum doesn’t corrode and is therefore ideal for humid areas like outdoor locations.

PVDF-coated or Painted Aluminium Circle for Decorative Items

The aluminum circles have been used for decorative purposes for signage, architectural elements, and even as signs because of their flexibility for surface treatments.

- PVDF Coating: PVDF coatings are an impervious fluoropolymer coating that protects against UV and weather as well as vivid colors for wall cladding.

- Painted Finishes: Spray-painted or powder-coated aluminium circles are commonly as namesakes, home decor and other artistic installations.

- Custom Shapes & Designs: Aluminum allows designers to create intricate custom designs and shapes through laser cutting, embossing or creating intricate patterns on elegant panels or interiors with luxury.

- Longevity: Aluminium provides superior durability in comparison to plastic or wood that are not subject to being rotting, warping or turning discolored with time, which makes it the ideal material for the most expensive decorative uses.

What are the Common Alloys of aluminium circle sheet?

The Common Alloys of aluminium circle sheet

The aluminum circle sheets are available in different alloys to satisfy the requirements of various industries and offer properties that are specifically designed to be used in various industrial applications. The choice you make will depend on the elements that determine strength, as well as the capacity to form, resistance to corrosion and the thermal conductivity. Here are the most widely employed alloys:

- 1050 and 1060 (Pure Aluminium Series)

They have over 97% of aluminium which makes them extremely resistant to thermal and corrosion, as well as conductors. They’re flexible enough to be used in various applications like reflections of cookware as well as chemical containers and cookware.

- 3003 (Manganese-Alloyed Series)

Manganese is used to enhance durability. 3003 has greater work-ability and durability than pure aluminum and still has outstanding resistance to corrosion which makes it a sought-after option in lighting fixtures, kitchenware and various other general fabrication projects.

- 5052 (Magnesium Alloyed Series)

5052 is well-known for its remarkable weldability and tensile strength, which makes it the ideal option for automotive, marine and industrial uses. Furthermore it’s resistance to corrosion caused by saltwater makes 5052 a good choice for construction of vessels and gas storage tanks.

- 6061 (Magnesium-Silicon Alloy)

The alloy that is treated using heat gives the best durability and machinability. This is the reason it is extensively employed in aerospace structural components as well as other mechanical applications that require high stress.

- 8011 (Al-Fe-Si Alloy)

8011 is commonly used for closures and bottle caps due to it has superior sealability and shapeability and strength as is the case. It is a reliable food packaging items.

Each alloy is selected according to the requirements of the specific application in order to provide the best performance in industries ranging from food preparation up to aviation. Manufacturers often pick from these alloys when selecting the best alloys to satisfy their costs as well as endurance and practical requirements.

Final

Aluminium circle sheets are essential in every industry from food processing to aerospace due to their lightweight weight, durability and pliability. The manufacturing process is guaranteed to be of the highest quality as well as the variety of alloys and surfaces permit the customization of specifications. Whether it’s for non-stick pans, anodized lighting or ornamental panels made of aluminum, circles are the preferred choice by companies across the world.

Are you seeking more information on a certain metal or product? Contact Lanren We look forward to providing you with top-quality products and services!

Related Products