3000 Series Aluminum Properties and Applications

Aluminum alloys are now the leading material choice for many sectors thanks to their malleability, low weight, and great corrosion resistance. The 3000 series aluminum alloys are the stars of this show with their specific properties, and are easy to adapt. In addition to their main elements – aluminum and manganese, the alloys have shown their way to be applied to many other application areas, from packaging to construction, and to form a unique appearance. Here we provide the potential, future, and demand for aluminum in the world, in addition to focusing on the properties, applications, processing techniques, and market outlook of the 3000 series aluminum.

Chemical Composition and Physical Properties

The 3000 series aluminum alloys have a name based on their chemical composition, which has a large effect on their mechanical and physical properties.

Chemical Composition of 3000 Series Aluminum Alloys

Aluminum is the primary and initial component in 3000 series aluminum, which is more than 96% of its material. Manganese is the primary ingredient for the alloy, mostly ranging between 1% and 1.5%. Other than manganese, a small proportion of other materials, such as copper, iron, and/or silicon, can also be used for its production for better standardized properties. The percent value for manganese, along with other materials, can be different for specific materials in the 3000 series, such as 3003, 3004, or 3105.

Physical Properties of 3000 Series Aluminum

Density: Approx. 2.73 g/cm³, which is way less by mass than steel (7.85 g/cm³) and suitable for relatively lightweight applications.

Melting Point: In the region of 650°C.

Thermal Conductivity: Relatively high – about 50-60% of copper, given the balance between heat transfer efficiency and cost-effectiveness, rendering it suitable for heat transfer applications.

Electrical Conductivity: Moderate, a little less than pure aluminum. A conductivity of 50–55% IACS means it is an excellent heat-conducting component.

Corrosion Resistance: Excellent. Essentially equivalent to pure aluminum, so it possesses excellent resistance to exposure to the atmosphere, fresh water, and organic acids (e.g., food-grade environment). However, surface treatment (like anodizing) is a must to get relief in prolonged exposure to acidic solutions of pH less than 4.0.

Workability: This composition provides good weldability (TIG/MIG) and tolerance to cold-working, like bending and rolling. This allows the manufacturing of complex parts, processes used typically in electrical goods.

- Physical Properties: Variable based on an alloy and temper.

- Tensile strength: 150–185 MPa, depending on the H14 temper condition.

- Elongation: 8–16% (based on temper state), providing maximum formability for subsequent stamping and deep-drawing processes.

The Brinell hardness number (HB) for unhardened metal lies between 30 and 40.

Applications of 3000 Series Aluminum

The adaptability of the 3000 series aluminum has enabled its integration into multiple industries. Below is a table summarizing the industries, specific applications, common alloys, and advantages of 3000 series aluminum.

| Industry | Specific Applications | Common Alloys | Advantages |

| Food and Beverage Packaging | Beverage cans, food foils | 3003, 3105 | Corrosion resistance, non-toxicity, lightweight |

| Home and Building Decoration | Roofing, cladding, decorative panels | 3003, 3004 | Aesthetic appeal, durability, excellent weather resistance |

| Home Appliances & Electronics | Refrigerators, washing machines, heat sinks | 3003, 3105 | Lightweight, corrosion resistance, good thermal conductivity |

| Daily Small Commodities | Cookware, containers | 3003, 3005 | Non-toxic, durable, easy to clean |

| Transportation Equipment | Automotive body panels, fuel tanks, marine components | 3003, 3105 | Lightweight, enhances fuel efficiency, corrosion resistance |

| Chemical Equipment | Storage tanks, heat exchangers | 3003, 3004 | Excellent corrosion resistance, good thermal management |

With its comprehensive performance, 3000 series aluminum has deep penetration from traditional packaging to high-tech products. In the future, its application scenarios will be further expanded under the trend of lightweight and environmental protection.

Processing Technology

Efficient manners are significant in bringing out the best in 3000 series aluminum. These are the basic methods determining the quality, performance, and applications of the ultimately produced goods.

The Script:

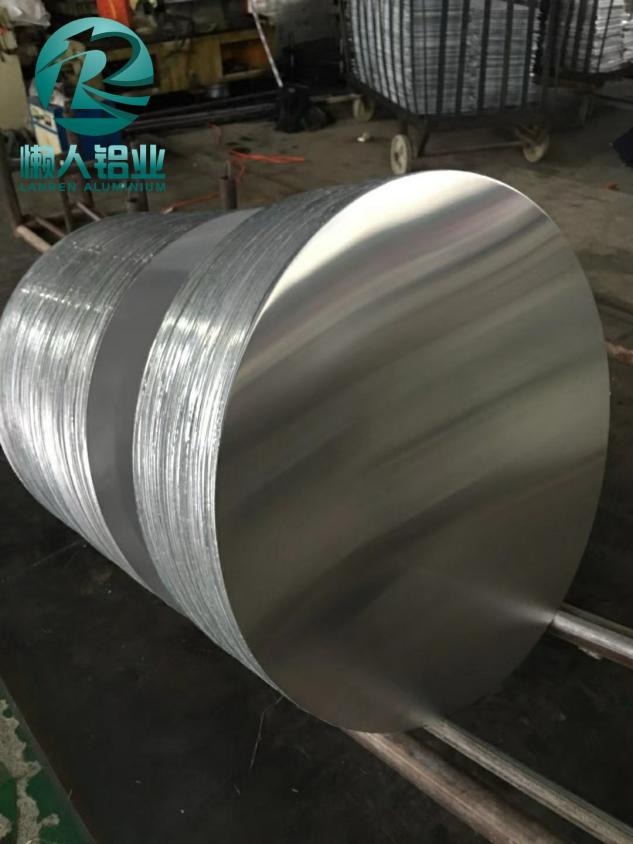

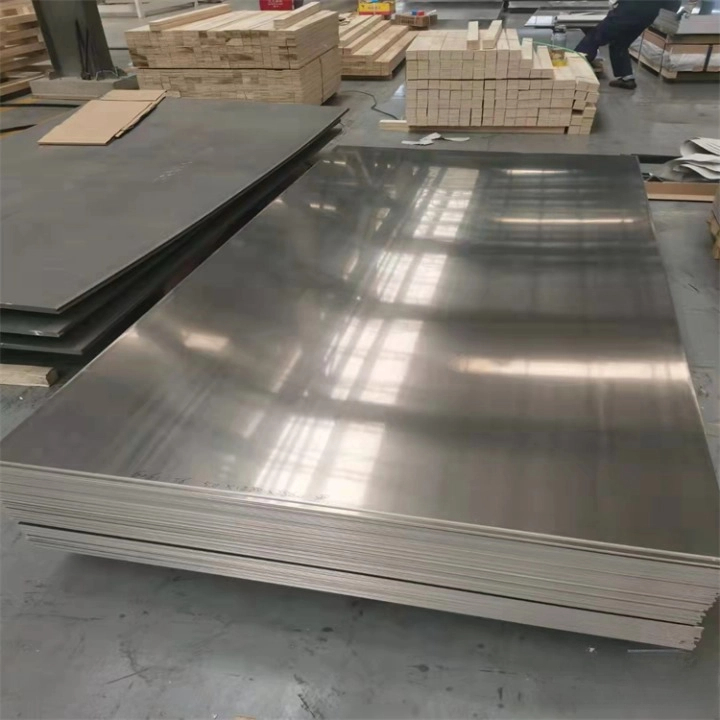

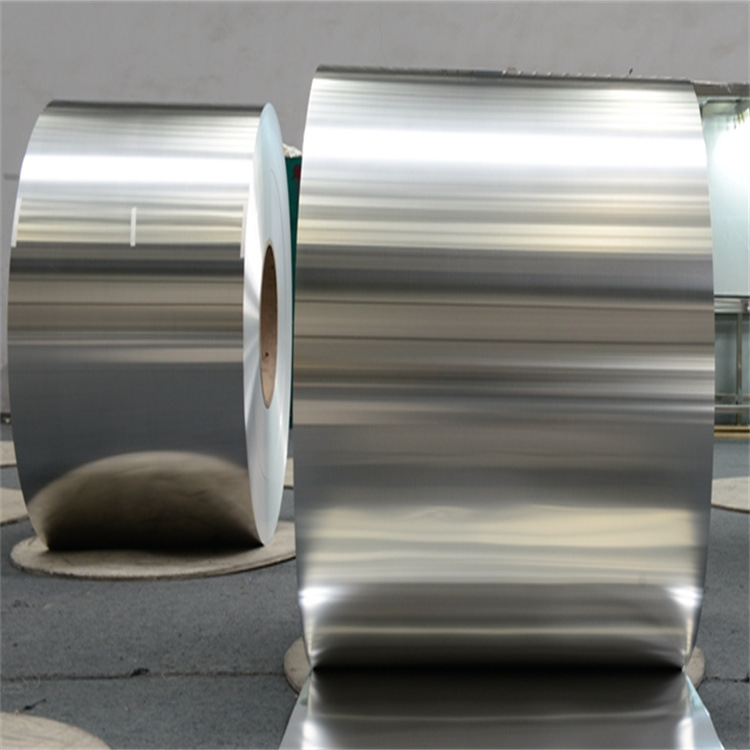

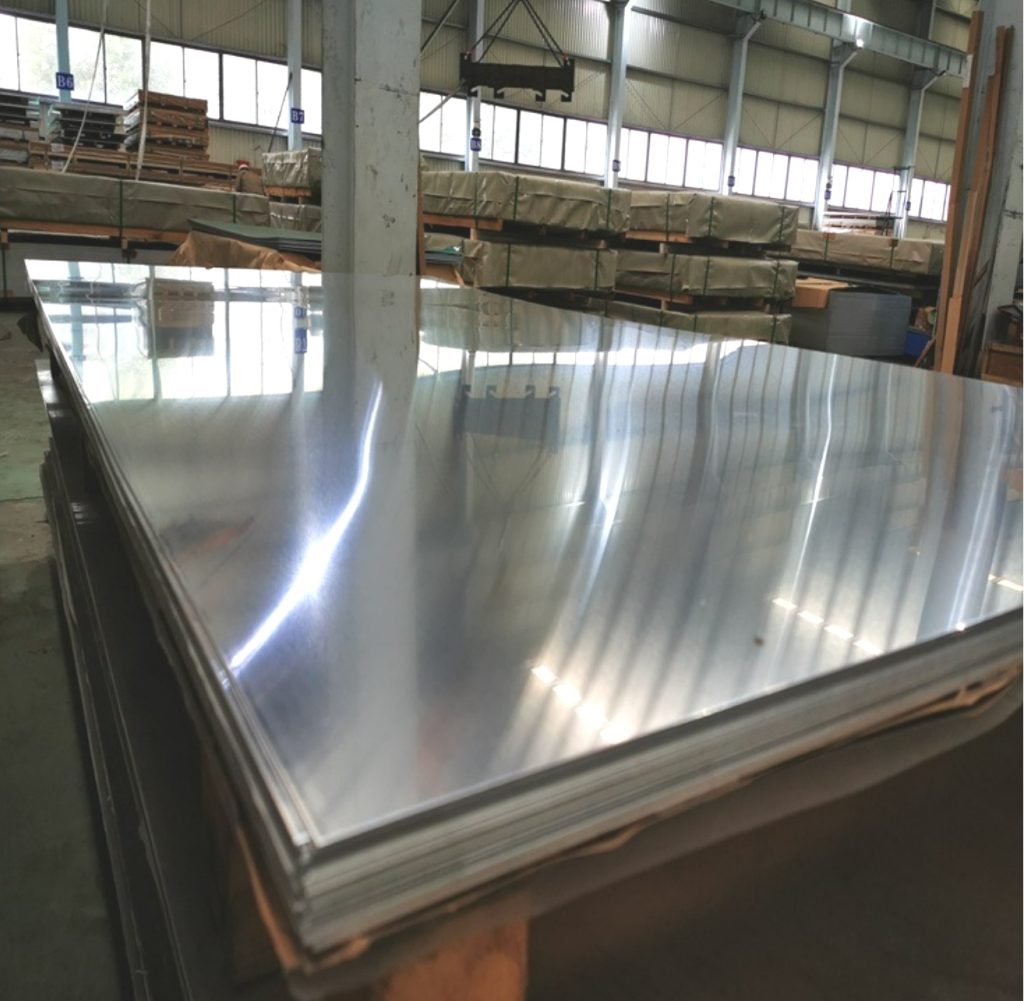

- Rolling: Making him get his hands on sheets and foils and using them for packaging and construction.

- Extrusion: One of the few ways to get used to aluminum for windows, doors, and structural components.

- Casting: Opening the door to form complex shapes for industrial applications.

- Welding: Allows for joining aluminum module assemblies in the automotive and structural industries.

- Surface treatment: The anodizing and painting surface finishes can improve corrosion resistance dramatically and give a finish.

Flexibility of the 3000 series aluminum to be processed by many ways has opened versatile options for manufacturers to see to various application needs.

Market Situation

The global demand for the 3000 series aluminum alloys continues to soar, mainly driven by their extensive range of applications in all respects, as well as the unique properties it exhibits.

Increasing use of sustainable packaging, coupled with low-mass transportation solutions and energy-efficient appliances, has opened up an expanding technology base and investment in both alloy design and processing techniques within the industry for greater application scope.

Challenges

-Biulousness in the raw material prices: Prices of aluminum and manganese are essential to affecting production costs linked to the 3000 series of these alloys.

-Stringent environmental policies: There may be some impact on production operations because of massive environmental regulations very soon.

-Rapid advancement in technology: Advancement in the processing and manufacturing technologies directly affects the competitiveness of various aluminum products under the 3000 series.

The market of the 3000 series aluminum extrusion is underlined by a nexus of diverse economic, technological, and sustainability factors. Nevertheless, it plays a significant part in both traditional and emerging markets, so that technological innovation and market demand dynamics are one of the areas of intense industry engagement. Just get in touch with us if you require any 3000 series aluminum.

Related Products