What Are Aluminium Trim Coil Used for?

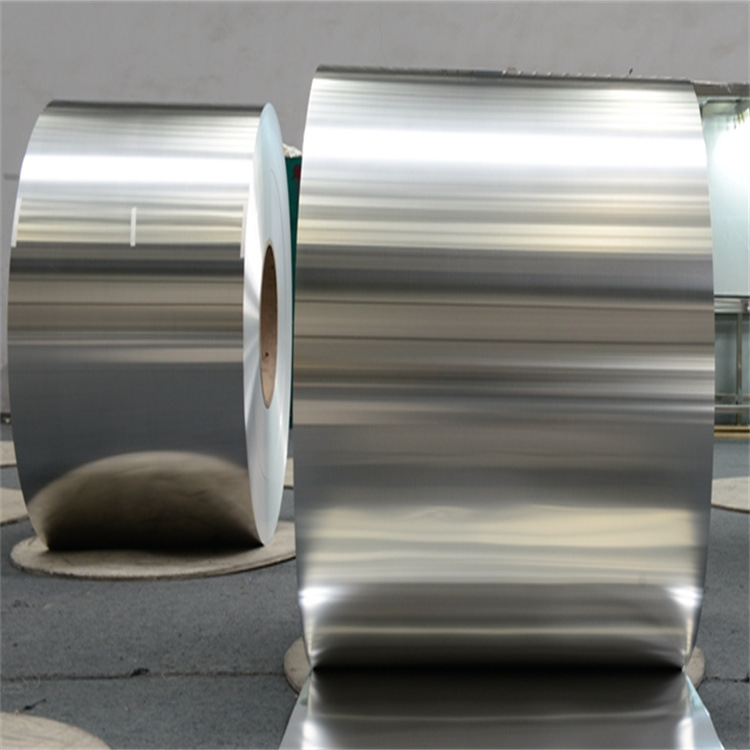

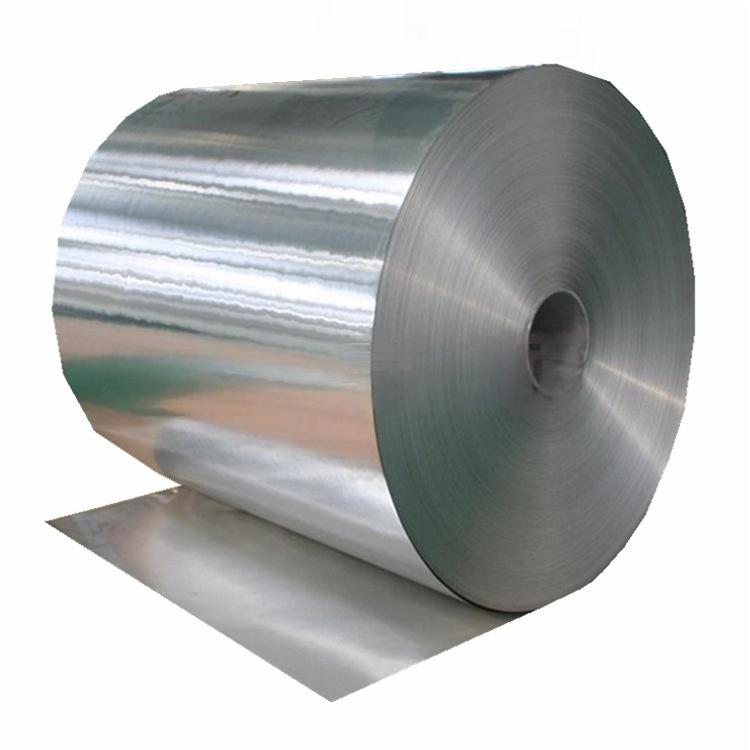

Aluminium trim coil appears in building sites and factory floors simply because it is corrosion-resistant and yet as light as air. That lightness and inherent rust-proofing make the metal very forgiving and a cinch to work with. Whenever laborers need flashing, trim, or a tough back skin for devices, they reach for the coil immediately. The roll maintains its shape, curves nicely, and looks good after exposure to years of rain and sun. A quick examination of the surface will usually determine the question of quality: smooth, even gloss with no pitting guarantees that the alloy will last.

Construction laborers, automotive assemblers, and general manufacturing operators stock a supply of the material on hand because it pays for itself in labor saved. Once the material has acquired that reputation, the conversation turns to the investment itself. Prepayment orders are less whimsical than huge fixed assets if the coil can be readily sold back into cash on short notice. A modest prepayment order, paid in advance, enables suppliers to hold prebooked melts in front and keep their mills running. That stability can turn a repeating expense with ease into an infrequent financial win on a quarterly report.

What is Aluminium Trim Coil?

Job sites and factory floors have aluminium trim coil because it will shrug off corrosion and will still weigh next to nothing. That lightness and built in rust proofing make the metal pretty forgiving and fast to work with. When crews want flashing, trim, or a tough back skin for equipment, they reach for the coil without thinking twice. The roll keeps its shape, bends clean, and looks good after years of sun and rain. A quick look at the surface will usually settle the question of quality: smooth, even sheen with no pitting tells you the alloy will hold up.

People in construction, automotive assembly, and general manufacturing keep a stock of the stuff on the shelf because it pays for itself in saved labor. Once the material earns that reputation, the conversation shifts to the actual investment itself. Purchasing commitments wobble less than big fixed assets if the coil can always be turned back into cash on short notice. A small advance order, paid upfront, lets vendors book melts in advance and keep their mills moving.

Main benefits are:

- Light and Simple to Install: Decreases handling during cutting, labor costs by a lot

- Weather-Resistant: Provides better performance at extreme temperatures and damp conditions.

- Low Maintenance Requirements: Maintains a good appearance without the need for regular upkeep.

- Eco-Friendly: Easy and eco-friendly building material for easy green building practices and recycling initiatives.

Aluminium trim coil offers an economical and cost-saving alternative to many uses in roof, siding, automotive trim, and industry, allowing roofers beautiful, professional-looking roofing panels without the cost and durability.

Classifications of Aluminium Trim Coil

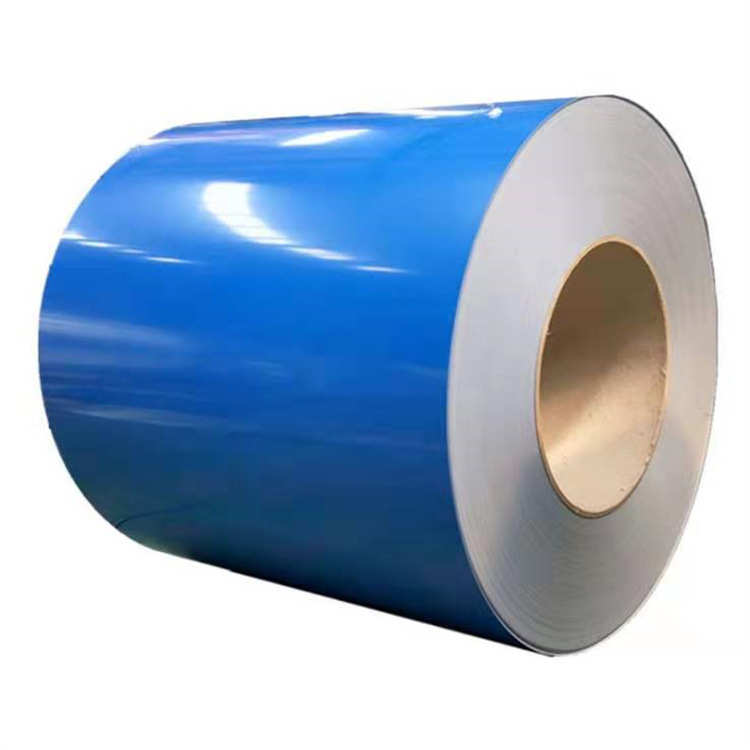

Aluminium trim coil is available in different variations based on finish and color, allowing for flexibility in both functionality and aesthetics. Below is a breakdown of the common types:

By Finish

| Finish Type | Key Features | Best Used For |

| PVDF Coated | – Superior UV, chemical, and weather resistance – Long-lasting color retention | High-end architectural projects, exterior cladding |

| Polyester (PE) Coated | – Cost-effective – Good durability and color options | Residential siding, roofing trim, general construction |

| Anodized | – Enhanced corrosion resistance – Metallic, sleek appearance | Coastal buildings, industrial applications |

| Mill Finish (Uncoated) | – Raw, untreated aluminium – Can be painted or coated later | Industrial uses, fabrication before finishing |

By Color

| Color Type | Key Features | Popular Applications |

| Solid Colors | – Wide range of standard shades (white, black, bronze, etc.) – Uniform appearance | Roofing, siding, window trims |

| Metallic & Glossy | – Reflective, premium look – Resistant to fading | Luxury buildings, automotive trims |

| Woodgrain & Textured | – Mimics natural wood or stone – Scratch-resistant | Decorative panels, interior design |

| Custom Colors | – Tailored to specific design needs – Special-order finishes | Brand-specific signage, unique architectural projects |

Aluminium trim coil provides versatile solutions to meet a range of application requirements in harsh climates or aesthetic needs, from weatherproof PVDF-coated coils for harsh weather environments to woodgrain finishes for aesthetic purposes.

The Most Common Applications of Aluminium Trim Coil

Since we know the many types of aluminium trim coil, how are they applied in various industries?

Here are the details.

Roofing and Siding Trim

“Aluminum trim coil” refers to coil sheathing made of aluminum. It has protective trim uses on roofs and siding to give weather-seal shipping and weather-seal protective attributes to cut edges. It also has a polished finish. It is used for:

- Drip edges and fascia boards: They prevent moisture damage by protecting the walls and roofs from water ingress.

- Soffit panels: They give them ventilation.

- Gable and corner trim: It gives them added structural support and increased curb appeal with custom paint.

Aluminum trim coil does not rust and is fade-resistant, making it a perfect choice for residential and commercial properties to withstand extreme weather conditions.

Automotive Trimming

Aluminium trim coil is widely utilized across the automotive industry for both functional and aesthetic applications:

- Body Moldings & Bumpers: Provide crash protection while also reducing vehicle weight to increase fuel efficiency.

- Door & Window Trims: Improve the door and window looks with a sleek finishing feature by providing corrosion-resistant edges that can even withstand ruthless weather conditions.

- Interior Panels & Accents: Interior panels & accents can deliver a stunning, fashionable look to bespoke car constructions.

- Anodized Finishes: Increase scratch and UV resistance by enhancing resistance to these variables.

Window and Door Framing

Aluminum trim coil is used in window and door systems because of its aesthetically pleasing look as well as its ability to withstand nature’s effects. The benefits of using aluminum coil trim are as follows:

- Weatherproof Seals: Prevent air and water leaks and reduce energy bills.

- Modern Slim Profiles: Offer modern and slim profiles that do not sacrifice strength to earlier designs.

- Low Maintenance: Aluminum will not warp, rot, or need frequent painting as wood and steel do. Powder-coating and anodizing make paint adhesion stronger, making it ideal for high-stress and high-traffic areas. Coatings will be resistant to UV breakdown and scratching.

HVAC & Industrial Applications

Aluminium trim coil is a necessity in HVAC (heating, ventilation, air conditioning) applications and industrial environments; it is irreplaceable due to its desirable characteristics. These coils perform numerous functions, such as:

- Ductwork & Ventilation Systems: Due to its non-corrosive qualities, clean airflow and longevity are guaranteed, providing quality air for good performance and lifespan.

- Machine Guards & Enclosures: Give equipment cover while being light enough to be transported.

- Conveyor and Panel Trims: Used in production lines to provide smooth, wear-free edges with zero wear factor over the long term. Their high thermal conductivity also makes aluminium a viable material for heat exchangers and cooling systems, and further, its ease of working makes it easy to tailor-made industrial applications.

Need to Invest in Aluminium Trim Coil?

Aluminium trim coil investment brings many advantages for construction, automotive, and industrial uses. Its lightweight yet sturdy nature facilitates installation and long-term performance, while its corrosion-resistance makes it suitable for harsh environments. Plus, aluminium trim coil requires minimal upkeep with cost-effective options available in different colors to meet every design need.

Businesses and contractors seeking high-quality aluminium trim coil must partner with reliable suppliers, like Lanren Aluminium. As one such trusted manufacturer and supplier of premium-grade trim coils with PVDF, PE, and anodized coating options to meet diverse project requirements.

Lanren Aluminium’s premium trim coils will bring added luster to any project – so reach out now for the best solutions!

Related Products