Why Color-Coated Aluminum Coils Are the Ideal Choice for Eco-Friendly Building Materials

There has been increased demand by builders and architects for green building materials in recent times. Developers also prefer judicious material utilization to be friendly to Mother Nature while attaining functional objectives. Color-coated aluminum coils are one such material, increasingly popular due to its versatility. It offers strength and refinement while being eco-friendly, thus an ideal building material for green building construction.

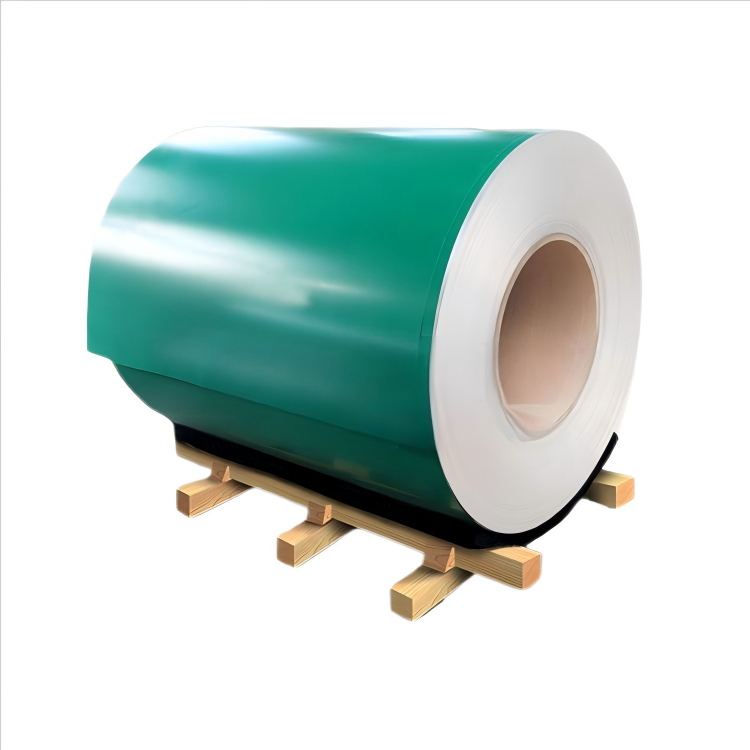

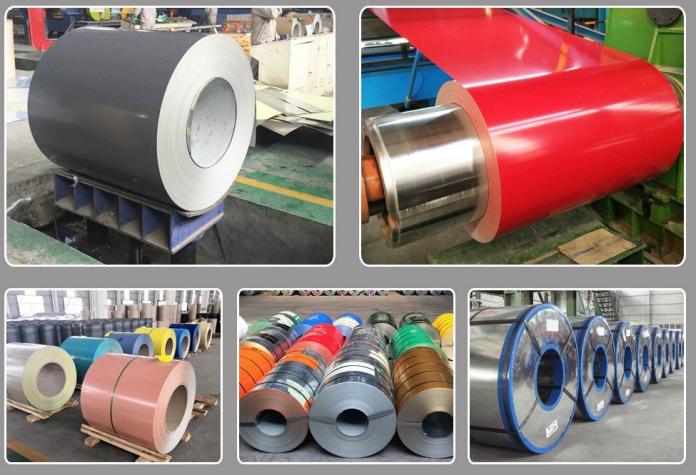

Common Types of Color-Coated Aluminum Coils

Color-coated aluminum coils come in various types, each designed to meet specific needs in construction and architecture. Here are four of the most common and widely used types of color-coated aluminum coils:

Wood Aluminum Coil: This wood-look color-coated aluminum coil mimics the appearance of natural wood while maintaining aluminum’s toughness and strength. It is used extensively in home and commercial settings, especially for architectural finishes, interior design, and fashionable facades. Coils that combine the beauty of wood with the maintenance-free and durable qualities of aluminum are an excellent option for green building projects.

Marble Grain Aluminum Coil: For a more luxurious and high-end look, marble grain aluminum coils replicate the elegance of marble stone. The finish is ideal for high-end building projects and provides a classic, natural beauty without natural marble’s cost and maintenance. Marble grain aluminum coils find wide use in architectural cladding, interior panels, and decorative facades, providing both aesthetics and strength in an environmentally friendly way.

Fluorocarbon (PVDF) Color-Coated Aluminum Coils: PVDF-coated aluminum coils are highly regarded for their remarkable durability and ability to withstand severe weather conditions, making them a popular choice for commercial and industrial structures. The fluorocarbon coatings, such as PVDF, provide excellent UV resistance, color stability, and protection against corrosion. These coils are perfect for exterior applications that require long-lasting performance and low maintenance, such as curtain walls, roofing, and facades in environments with high exposure to the elements.

Polyester (PE) Coated Aluminum Coil: Aluminum coils that are polyester-coated can also be used for residential and commercial construction, as they are multifunctional and economical. These coils exhibit a glossy sleek finish, which is also highly weather-resistant and does not fade easily. PE coatings are also perfect for outside use as they provide excellent color retention and resistance to UV rays, which is highly suitable for exterior cladding, window frames, and decorative panels. These coils are best for several uses because they provide a high-quality finish at a very reasonable price, along with their impressive durability.

Environmental Benefits of Color-Coated Aluminum Coils

Aluminum coils coated in color are durable, beautiful, and provide long-term aesthetic value. They are also eco-friendly, which is important to construction developers.

- Energy Saving: Reflective surfaces reduce heat absorption, which improves energy efficiency. Color coated aluminum coils help reduce the reliance on air conditioning in climate-controlled spaces, and in turn reduces energy consumption and greenhouse gas emissions. Constructing energy-efficient buildings helps support environmentally friendly development.

- Recyclability: No other material holds value as aluminum does. More importantly, aluminum can be recycled infinitely without losing any value. Color-coated aluminum coils fit into the circular economy exceptionally well as they allow resource recovery, value retention, and waste reduction.

- Low Maintenance: Unlike other building materials which easily weather and require almost constant upkeep, color-coated aluminum coils need no washing, repainting, and no toxic chemicals. This affects other overhead costs as there will be less water and chemicals needed. This will also positively impact the environment.

- Lifespan & Impact on Waste: Aluminum coils last a very long time, and that helps cut down on waste. Because these materials do not fade, corrode, or weather, they do not need servicing or repairs for decades. This helps avoid unnecessary environmental impacts.

- Reducing Urban Heat Impact: Urban areas experience a temperature rise and increased pollution due to human activities such as energy use and unnecessary use of air conditioning. Construction with colored aluminum coils helps fight this problem. Their reflective properties lower the temperature around the shaded areas of the building, which helps lower the air conditioning demand on the lower floors. This means the building helps meet energy efficiency targets. This is a small step but a necessary one to combat global warming.

The environmental advantages of color-coated aluminum coils make them an intelligent and sustainable option for green construction. Their capacity to save energy, minimize waste, and reduce maintenance needs aligns with eco-friendly building practices, ultimately promoting a healthier planet.

Practical Applications of Color-Coated Aluminum Coils in Construction

Color-coated aluminum coils are highly versatile and serve various practical purposes in construction. Below are the three most significant applications, detailed for a clearer understanding of their benefits in modern building projects:

Exterior Cladding and Facades

Watertight aluminum coils are crucial for exterior cladding and facade work. They provide an attractive finishing touch and plasticity to the structure, which increases its lifespan. Cladding shields buildings against environmental conditions, including rain, snow, wind, UV radiation, super frost avalanche, and extreme heat. The coatings used today are made of polyester or PVDF, and they endure fading, corrosion, and weathering for years, ensuring that the facade stays beautiful long into the future. Aluminum also has a very low thermal conductivity compared to other materials, allowing it to reflect most of the rays, which minimizes internal heat absorption; thus making temperature control inside the building easier and increasing the energy performance of the construction.

For modern architecture, designers need to incorporate contemporary sophisticated styles while still meeting practical standards. Luckily, designers have at their disposal a broad range of colors as well as finishes such as metallics or different texture effects, which allows them to create works of art.

Doors and Window Frames

The impressive durability, low maintenance, and various design options available make color-coated aluminum coils perfect for constructing door and window frames. Aluminum’s lightweight but strong properties allow it to fulfill the building’s structural and long term requirements. The color coating makes the material even more suitable for use outdoors, as it helps withstand corrosion, fading, and general wear and tear. The wide and varied options for color also helps designers harmonize door and window frames to the overall design of the building. The surfaces of color-coated aluminum are smooth and easily cleaned, which makes maintenance efforts, and therefore, frame upkeep, minimally intrusive. These attributes of color-coated aluminum coils prove to be an intelligent and environmentally friendly choice for construction, whether it be for private houses or commercial buildings.

Roofing

Aluminum Coils colored with specific shades provide immense UV protection to buildings and serve quite effectively as a coating over roofs. Other than providing fundamentals for any building, the coils also act as barriers to moisture, volatile organic compounds, pollutants, and many other ruthless environmental factors that can affect any building in its entire lifetime. The notch color-coded aluminum coats also add value by serving perpetual visual appeal and, during harsh weather conditions, help a building’s sand-suppressed floor appearance lift without going through too much wear and tear. This serves greatly from a long-term perspective.

Do You Need Bulk Color-Coated Aluminum Coils?

Purchasing bulk color-coated aluminum coils for large-scale construction projects can be efficient and cost-effective. One of the leading manufacturers of aluminum products, Lanren Aluminum, widely supplies color-coated coils for construction purposes. With over 15 years in business and a reputation for quality control, we know that our products are up to standard.

Suppliers who provide bulk buying options like Lanren Aluminum enhance material quality, speed up delivery times, reduce costs, and promote eco-friendly building practices all at once. Whether it’s commercialized or residential work, executed industrial or undertaken broad-scope projects, with this aluminum supplier comes reliable customer service coupled with logistics gratification, all tailored to bulk supply demands.

To view more information, please visit: LanrenAluminium.

Related Products