Aluminium Chequer Plate vs. Steel Tread Plate: Which is Better for Your Project?

If you are requiring a checkered plate for your project, common choices are steel checkered plate and aluminium checkered plate (also known as aluminium checkered plate). But what suits you best? Generally, you have to consider factors such as weight, strength, corrosion resistance, and cost. Consequently, in this article, we compare aluminium checkered plate and steel checkered plate and contrast their merits and demerits to aid your decision-making. We shall also provide some tips on how to select a good aluminium checkered plate supplier to acquire quality materials for your project.

What are Aluminium Chequer Plate and Steel Tread Plate

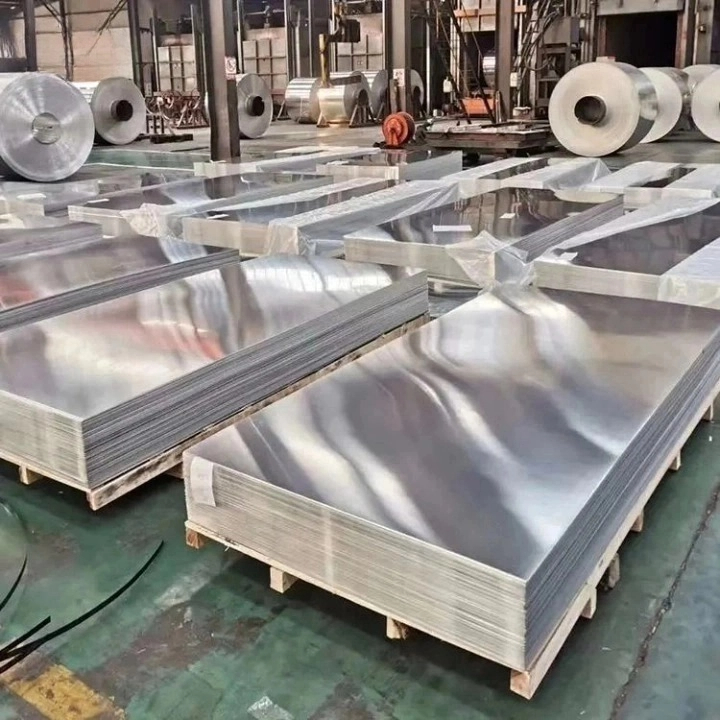

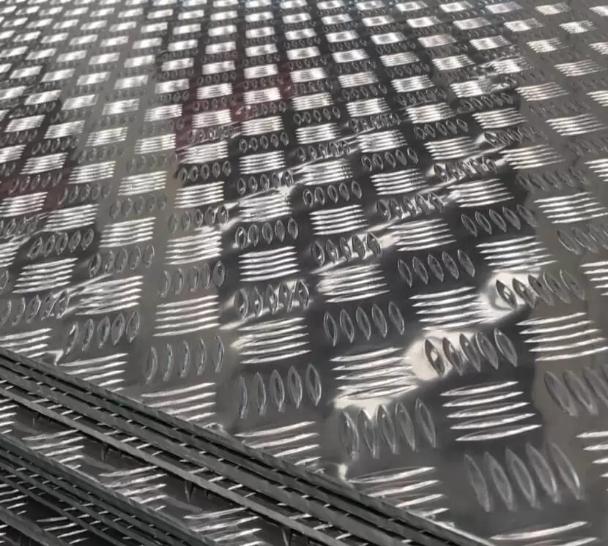

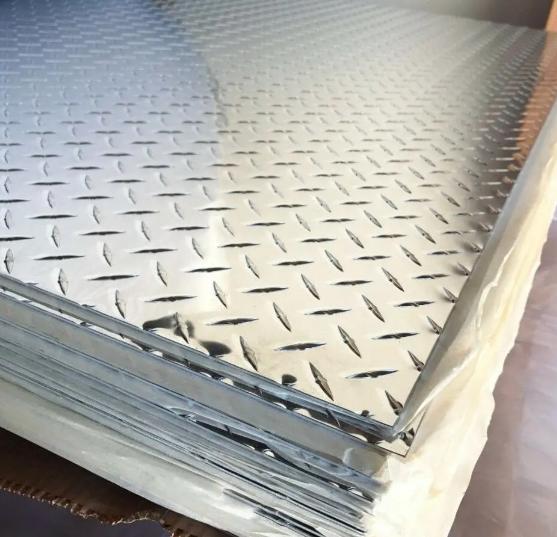

Aluminium Chequer Plate, or aluminium checker plate to give it its more popular title, is a light but unbelievably robust metal sheet featuring an unusual raised diamond or linear pattern on one or two sides. Its unrivalled surface structure gives absolute slip resistance, and Aluminium Chequer Plate is ideal for flooring, ramps and stair treads – and don’t forget marine applications! Manufactured of corrosion-resistant alloys such as 5052 or 6061, it is most often utilised in marine, transportation and building applications where rust resistance and weight savings are paramount; unlike steel, it requires no protective coatings, thus reducing long-term maintenance costs over its lifetime by a significant amount!

Steel Tread Plate is heavier and stronger, typically constructed from stainless or mild steel with embossed patterns to provide traction. Although the material possesses a greater load capacity for industrial flooring, machine pedestals, and heavy equipment applications, its corrosion tendency can raise maintenance expenditures in harsh environments; mild steel tread plates are most often less expensive upfront; however, stainless steel varieties can provide superior corrosion resistance at higher costs.

Both play fundamental uses in construction and manufacturing, but the right material for your project is a function of weight, corrosion resistance needs, amount of strength required and price. Their variances are what assist in choosing the right material.

Aluminium Chequer Plate: Pros and Cons

When selecting materials for industrial, marine, or architectural applications, aluminium chequer plate (also known as aluminium checker plate) is a popular choice due to its unique properties. However, like any material, it has both strengths and weaknesses that must be considered before making a decision.

Key Advantages of Aluminium Chequer Plate

Here are the common pros of Aluminium Chequer Plate:

- Improved Corrosion Resistance: Aluminium’s natural protective oxide layer provides it with improved corrosion resistance compared to steel, making it a perfect choice for offshore, chemical plant and external structures that are exposed to dampness, salt or harsh weather.

- Slip-Resistant and Safety Compliant: Increased diamond or linear finishes have superior anti-slip properties, thus being a safe option for walkways, stair treads, and car floorings. Also, compared to painted steel flooring options, their grip does not become ineffective even after years of service.

- Aluminium Chequer Plate Is Lightweight Yet Durable: Aluminium chequer plate is significantly lighter than steel, which saves time and cost in transportation and installation processes. While its lightness may limit transportation and installation costs, aluminium does not lose sufficient structural strength because of better-grade alloys such as 5052 or 6061 that are commonly applied in aerospace and automotive industries.

- Low Maintenance Cost & Long Life: Aluminium does not rust, so its long-term cost of maintenance will be much lower than that of the metal counterparts. Painting and galvanising needs are also not required, so aluminium is a cheaper long-term solution.

Potential Limitations of Aluminium Chequer Plate

Before Choosing Aluminium Chequer Plate, consider the following Potential Limitations:

- Low Capacity to Bear Loads in Comparison with Steel: Aluminium is stronger in comparison to weight, but it falls short of the rigidity offered by steel, thereby rendering steel a suitable choice for operations involving repeated heavy equipment operation (e.g. repeated heavy equipment operation on industrial platforms).

- High Initial Cost: Aluminium chequer plate typically has a higher initial cost than mild steel, but savings in maintenance and replacement over time often offset this initial cost.

- Softer Surface: Vulnerable to Denting: Aluminium is simpler to dent and scratch than hardened steel, hence heavier gauges (5 mm+) can be employed in situations of repeated impacts.

- Low-temperature Limiting Performance: Aluminium begins to deteriorate at temperatures higher than 150degC (302degF), thus it is not suited for employment where high temperature (e.g. furnace conditions), where the steel possesses significantly superior performance.

Steel Tread Plate: Pros and Cons

It is a tough robust, heavy-duty product that is widely employed in high-traffic and industrial areas. Its durability and strength make it an ideal option for projects that require a high load-bearing capability. However, it comes with certain drawbacks which buyers must consider.

Advantages of Steel Tread Plate

One of the most significant advantages of tread plates made of steel is its incredible strength that makes it suitable to be used for stair and industrial floors and platforms for machinery where massive loads are required. As opposed to aluminium, steel is able to stand up to abrasion and significant impacts without warping or bending. Another benefit is the low initial cost. Mild steel tends to be less expensive than aluminium, which makes it an economical choice to large-scale construction projects. In addition, steel is easy to fabricate and weld which allows for custom-made modifications for structural projects.

Disadvantages of Steel Tread Plate

The most significant drawback to tread plates made of steel is its weight, making the installation and transportation more labor-intensive. As opposed to aluminium, steel extremely prone to rust, particularly in moist or corrosive environments. To avoid corrosion the tread plates of steel often require protective coatings, such as galvanization or paint. This adds to the costs of long-term maintenance. In the absence of proper treatment the rust could affect the appearance and the structural quality of the material in time.

Due to its strength and strength, steel tread plates are the best choice for heavy industrial uses, like factories floor, fire escapes or construction equipment. If, however, corrosion resistance and light weight properties are the primary concern the aluminium chequer plates could be a better choice.

Aluminium Chequer Plate vs. Steel Tread Plate

When deciding between steel tread plate and aluminium chequer plate, one needs to understand their primary differences.

Aluminium chequer plate offers greater corrosion resistance and lightness, making it ideal in areas where weight saving and weather toughness are a priority. Aluminium possesses a continuous oxide protective coating that does not need additional coatings.

Steel tread plate offers added structural integrity and impact resistance, the preferred choice for heavy industry application. However, as being prone to corrosion, most steel plates must be protected through galvanizing or powder coating when used above ground.

Subsequently, we compare in explanations and side-by-side table.

| Comparison Factor | Aluminium Chequer Plate | Steel Tread Plate |

| Weight | Lightweight (about 1/3 the weight of steel) | Heavy, adds structural mass |

| Corrosion Resistance | Excellent – naturally rust-resistant | Poor – requires protective coatings |

| Strength | Moderate strength (good for most applications) | Very high structural strength |

| Maintenance | Virtually maintenance-free | Requires regular inspection and recoating |

| Cost Considerations | Higher initial cost, lower lifetime costs | Lower initial cost, higher maintenance costs |

| Workability | Easy to cut, form and install | Requires heavier tools for fabrication |

| Thermal Conductivity | Excellent heat dissipation | Acts as thermal insulator |

| Electrical Conductivity | High conductivity (may require insulation) | Naturally insulative |

| Recyclability | 100% recyclable without quality loss | Recyclable but may degrade in quality |

For transport equipment (truck beds, trailer decks) and marine environments, aluminium chequer plate is without question the better choice with its corrosion resistance and weight savings. The reduced weight translates to better fuel economy and capacity for loads.

In industrial floor and heavy equipment use where maximum strength is needed and weight is irrelevant, steel tread plate would be the price-conscious choice. With the ability to withstand repeated heavy impacts, it will suit factory floors and loading docks.

How to Choose A Reliable Aluminium Chequer Plate Supplier

Selecting the right aluminium chequer plate supplier is crucial to ensure quality, durability, and value for your project. Here’s what to consider when making your choice:

- First, verify the supplier’s material certificates, such as mill test certificates (MTCS), to determine the alloy grade (e.g., 5052 or 6061) and quality levels. A reliable supplier should provide documentation to verify the material’s authenticity.

- Secondly, experience and reputation become relevant—look for suppliers with a sound history in the business. Check customer feedbacks, case studies, and industry certifications to assess reliability.

- Customisation capabilities are also an important consideration. A good supplier must offer perforated, painted, or custom-cut aluminium chequer plates to meet specific project requirements.

- Pricing must be competitive without sacrificing quality. Obtain at least three quotes from suppliers and give preference to those that balance cost and material quality.

- Finally, consider logistics and customer support. A good supplier offers punctual delivery and excellent after-sales support.

Why Choose Lanren Aluminium?

Being a reliable aluminium chequer plate supplier, Lanren Aluminium provides premium, certified materials with a variety of customization possibilities. Boasting years of market experience, rigorous quality control, and friendly customer service, we provide you with the best products to suit your needs. Whether it’s standard or bespoke solutions, Lanren Aluminium provides reliability and performance.

Get in touch with us today for superior aluminium checker plate customized for your project!

Related Products